Advanced manufacturing capabilities

Exploring the possibilities of highly functional multilayer film

One of the main products sold by Moriroku Chemicals is highly functional multilayer film. Because it is an excellent material for ensuring product safety, hygiene, and precision, this film is mainly used in the medical equipment, food products, and electronic devices industries. Moriroku Chemicals' subsidiary, Shikoku Kakoh Co., Ltd., manufacturers the film using a co-extrusion technology it has refined for about 40 years. Moriroku Chemicals supplies this multilayer film to numerous industries, helping customers overcome various technical challenges.

Offering solutions to customers with co-extrusion technology

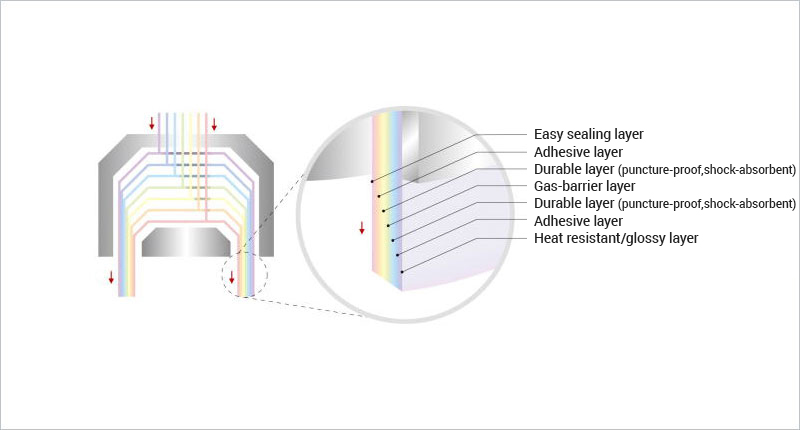

Shikoku Kakoh has been refining its core technology, co-extrusion, over the past four decades. The technology is applied to manufacture multilayer film by using two or more extrusion machines to extrude two or more of the same or different types of resin into multiple layers.

Co-extruded multilayer film is comprised of as many as eight layers, each with a thickness of several micrometers to form a film of fewer than 100 micrometers in thickness. Shikoku Kakoh possesses a technology that produces and laminates film all at once by controlling different casting temperatures in a metal die for each resin used to make a layer of several micrometers in thickness. This technology allows the company to develop and manufacture highly functional films that can form an impenetrable gas barrier, ensure excellent hygiene, and withstand shocks.

Moriroku Chemicals has been helping customers from a broad range of industries to deal with challenges that would be impossible to overcome without the use of film made by Shikoku Kakoh. By working closely together with customers as a developer and solutions provider, Moriroku Chemicals has earned a reputation as a company that can dependably adapt to customers' needs.

Co-extrusion manufacturing methodThrough co-extrusion, a multilayer film is made by melting several different resins and layering them inside a dye to form a single film. This not only enables highly functional film but also allows the film to be designed according to customers' requests.

Providing solutions for applications requiring safety and precision

Moriroku Chemicals works with Shikoku Kakoh to develop highly functional film for use as solutions mainly in the food products, medical equipment, and electronic devices industries.

In the food products industry, the film is used for food packaging, particularly processed meat. Representatives from both companies visit a wide range of production plants, from upstream meat processing plants to downstream processed food plants that make ham, sausages, and side dishes, to discuss issues faced onsite and optimally design film for various manufacturing processes.

Likewise, Moriroku Chemicals supplies Shikoku Kakoh's highly functional multilayer film to the medical equipment industry for use as packaging film, particularly for products that require a high level of safety, such as infusion bags, peritoneal dialysis bags, and packages for pre-filled syringes and disposable devices.

Meanwhile, both companies work together to develop and sell highly functional multilayer film to the electronic devices industry. Used as packaging materials for semiconductor devices and electronic components, the film is designed for extremely clean and anti-static environments.

Shikoku Kakoh's film used for the outer layer of infusion bagsMedical professionals are increasingly requesting transparent film for the outer layer of infusion bags so that the contents can be checked. Consequently, demand for highly durable and transparent barrier film is on the rise.

Japan's only manufacturer of corrugated plastic containersIn addition to producing multilayer film, Shikoku Kakoh has been manufacturing corrugated plastic containers made of polyethylene for about 40 years, and was the only company in Japan to make these products. The company can modify the hardness and shock absorption of the containers according to required specifications, allowing for a wide range of applications.

Photo: The containers are used for growing tree saplings.

Upgrading production facilities with the latest equipment

In July 2020, Shikoku Kakoh commenced operations of a new factory building at the site of its main multilayer film factory in Kagawa Prefecture following the transfer of operations from its former factory. By installing state-of-the-art equipment for improving hygiene and productivity, the company is making the most of its production facilities with the goal of increasing market share and developing new products. Furthermore, Shikoku Kakoh plans to venture into new business areas by leveraging the expertise and technical capabilities it has gained by supplying products to the medical equipment industry, particularly compliance with strict standards for safety and hygiene.

New factory constructedFilms used for hygienic purposes must be manufactured under very clean conditions. Shikoku Kakoh's new factory has an extremely hygienic environment with cleanrooms that meet Class 10,000 standards, and equipment for manufacturing film using high-pressure steam sterilization exceeding 120 degrees Celsius.

Other solutions

Contact us

MORIROKU CHEMICALS

MORIROKU CHEMICALS

Continue reading

Continue reading