Recycling and innovation

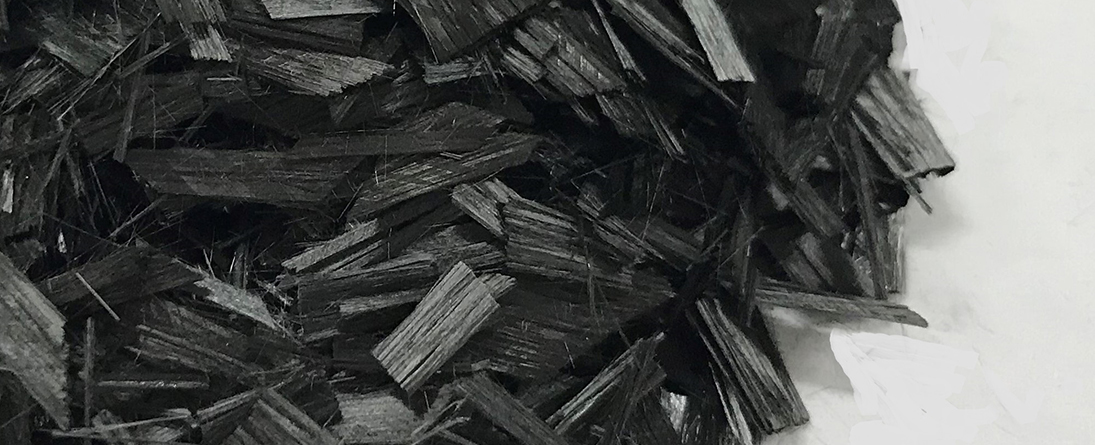

Creating new materials with a process for recycling carbon fibers

Carbon fibers are increasingly being used to make aircraft, automobiles, and sports equipment such as golf clubs and tennis racquets, but recycling the materials has been very difficult and expensive thus far. In that context, the Moriroku Group has taken on the challenge of recycling carbon fibers for use as materials in plastic auto parts. Through this initiative, the Group is broadening new business opportunities while also providing an important recycling solution.

Leveraging the advantages of carbon fiber while promoting sustainable production

Compared with steel, carbon fiber is only one-fourth the weight but ten times stronger per unit weight. Therefore, demand from the aircraft and automobile industries has been growing rapidly, and more applications are expected in the future in other industries, such as aerospace. Despite the benefits of carbon fibers, however, a widely used process for recycling the materials has not been established. When airplanes are retired from service, for example, the carbon fibers used to make much of their fuselages remain unused in large storage areas called "aircraft boneyards."

Recognizing this problem, the Moriroku Group has aimed to develop new materials made of recycled carbon fibers for use in auto parts. Toward this end, in 2018 Moriroku Holdings acquired a stake in Carbon Fiber Recycle Industry Co., Ltd., a Japanese company that has successfully developed a technology for removing only carbon fibers from scrap aircraft materials. Based on a traditional high-temperature firing method for making ceramic roof tiles, this innovative new technology enables one of the world's most efficient means of extracting carbon fibers, which allows them to be recycled.

Applying this technology, the Moriroku Group is working to develop molded products made with a combination of resin and recycled carbon fibers, and then use the materials to produce original auto parts that offer the added benefits of lighter weight and recyclability. The ability to repeatedly recycle the parts is particularly important because recycling carbon fiber scrap materials has been difficult up to now. Looking ahead, the Moriroku Group hopes this initiative will contribute to new recycling solutions and help the automobile and other industries move closer to achieving the United Nations' Sustainable Development Goal of ensuring sustainable consumption and production patterns.*

The goal is one of the 17 Sustainable Development Goals adopted by the United Nations Summit on Sustainable Development in 2015. Covering issues ranging from poverty and hunger to inequality, energy, and climate change, the goals are intended to be achieved by 2030.

Developing parts made of recycled carbon fibersMoriroku Technology has been developing lightweight parts for automobiles and motorcycles using functional plastic materials developed by Moriroku Chemicals.

Overcoming the challenges ahead to establish a new business

Leveraging its collective capabilities, the Moriroku Group is working towards having its all-new auto parts adopted by automakers and establishing a recycled carbon fiber auto parts business. To accomplish these goals, Moriroku Chemicals is coordinating efforts among its business partners, refining recycling technologies, and working to obtain carbon fiber scrap materials. At the same time, Moriroku Technology is developing the parts and marketing them to automobile manufacturers, including Honda Motor Company.

Many obstacles must be cleared, however, until plastic auto parts made with recycled carbon fiber can actually be adopted. First among them, automakers require a stable supply of a huge volume of parts. Therefore, a vast amount of carbon fiber reinforced plastic must be secured as raw materials. The best sources of these materials are scraps remaining after the production of aircraft parts and the fuselages of aircraft that have been retired from service. It is not easy, however, to secure a dependable supply of these materials, particularly used fuselages. That is because retired aircraft tend to be owned by low-cost carriers, which generally purchase used airplanes from major airlines. As the final owners, these low-cost carriers are responsible for disposal under current regulations, but individual carriers usually do not have a large amount of aircraft components that can be recycled. Therefore, negotiations and agreements must be concluded with many low-cost and major airlines until enough scrap materials can be supplied.

A number of years will be needed to complete the development of auto parts made with recycled carbon fibers because their properties must be repeatedly tested and quality must be assured. Even after the new parts are ready to be marketed, their performance compared with existing and upgraded parts will have to be verified because automakers are cautious about adopting new materials and parts. Therefore, Moriroku Chemicals and Moriroku Technology are actively sharing ideas and combining their expertise to overcome these challenges going forward.

Carbon fiber aircraft componentsCarbon fiber applications for aircraft have been increasing since the materials were first used for sections of airplane tails in the mid-1980s. As a result, a vast amount of carbon fiber components will need to be steadily recycled in the future.

Bringing benefits to industries and society through innovative materials

The next wave in the automobile industry is summed up by the acronym CASE, which stands for "connected, autonomous, shared, and electrified." Due to the wider use of electric batteries, in particular, vehicle bodies will need to be lighter than before. Consequently, lightweight plastic auto parts are expected to play an important role.

From that standpoint, the Moriroku Group is pushing ahead with its efforts to develop and supply lightweight auto parts made with recycled carbon fibers. The Group is confident that the innovative new materials and parts it is developing will not only benefit the automobile and recycled carbon fiber industries but also society as a whole.

Helping make next-generation vehicles more lightweightAutomakers increasingly need lightweight parts to make more fuel efficient cars. In response, Moriroku Technology is working to supply both interior and exterior auto parts made of strong and lightweight carbon fiber reinforced plastic.

More about us

Next three stories

Contact us

MORIROKU HOLDINGS

MORIROKU HOLDINGS