Decorative multilayer molding

Moriroku Technology proposes a myriad of interiors based on fusions of multilayer molding and lighting

As a manufacturer that specializes in resin parts for automobiles, we possess a diverse array of decorative technology, and pursue the possibilities of decoration that go beyond conventional varieties to include the coloring of raw materials themselves, film sticking, cover winding and coating. Here, we propose interiors and exteriors based on the application of decorative multilayer molding.

Presenting a luxurious look at a comparable cost to coating

Decorative elements used in automobile interiors generally consist of coating, wood grain tones and metallic tones. Given that, female engineers at Moriroku Technology set out to expand their ideas with their preferences and desired personal effects as their starting point, and pictured the possibility of realizing an interior with sense of translucency and luster not unlike that of an accessory or dress. Working together with designers at automobile manufacturers, they embarked on development in order to achieve flashy and brilliant high-appearance designs.

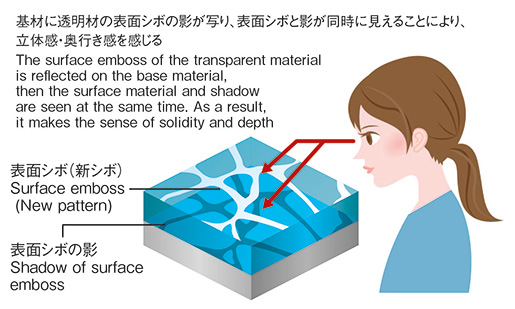

Using highly shockproof materials as substrates, they performed the extrusion molding of transparent materials on the surface layer that users would actually see to generate a sense of translucency, depth and luster.With embossing added to design aspects to lower shadows to the bottom of the transparent materials, the resulting subtle design alternates between being visible and invisible depending on the angle of incoming light. Additionally, a striking moire effect grabs people’s attention in the moments that it appears.

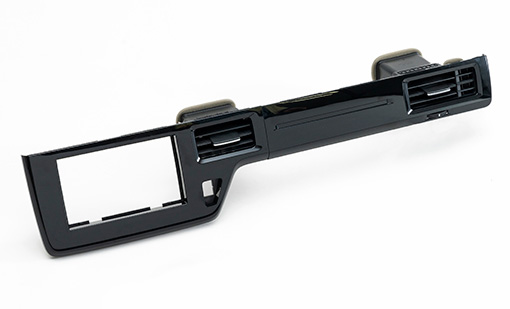

Examples of mass-produced parts

This is already an established technology of ours. That is precisely why we can offer it at a reasonable price point. It is employed in instrument panels in Honda’s “N-WGN” and “STEP WGN,” where it has been well-received.

Decorative possibilities expand with unfettered ideas

Combining films, surface treatment and other elements causes decorative possibilities to greatly expand even further.

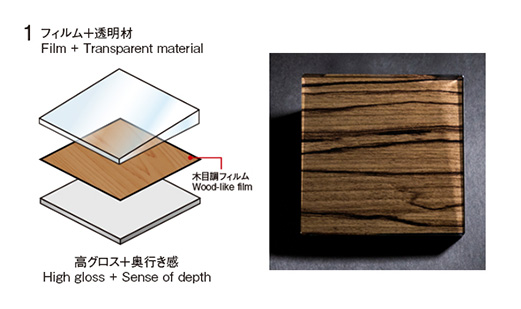

[Sample 1] has a three-layer structure. The first layer is made up of transparent materials whose thickness extends toward its depths. The second is a wood grain tone film. Finally, transparent materials have been used for the substrate.The aim behind this combination was to reproduce genuine wood grain similar to that featured in luxury automobiles.

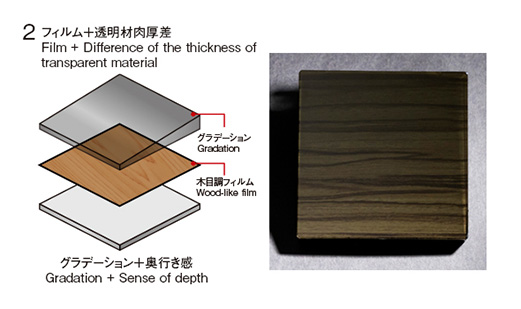

[Sample 2] is an example of the application of that technology, with semitranslucent coloring added to the initial layer. Because the level of translucency falls at further depths, a color gradient is visible through the wood grain.

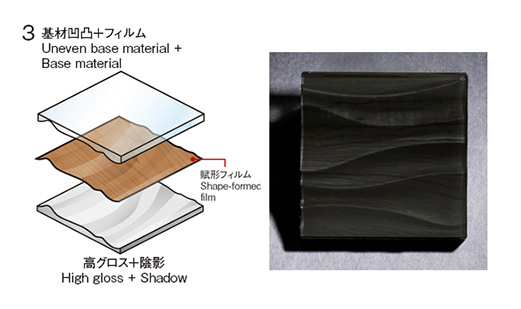

[Sample 3], like Sample 1, has a three-layer structure in which complementary 3D modeling is placed in the surface layer and substrate, with decorative film inserted between the two.While this decoration gives offa calm, subtle impression, its 3D modeling stands out when light hits it at an angle.

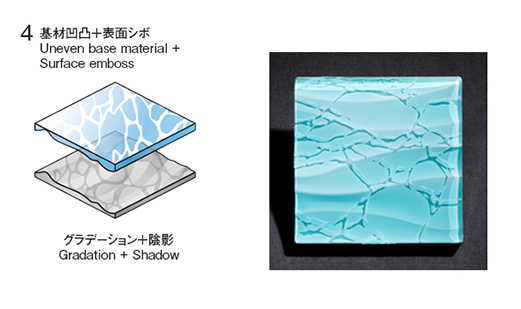

[Sample 4], a two-layer structure, consists of modeling meant to reproduce the water and sandy bottom of a beach.The top of the translucent resin on the surface layer has been embossed to appear as a ripple, with a sand-like unevenness carved into the substrate. Rays of undulating light shining through this sample is sure to recall scenes from the waterfront.

An outstanding complement to illumination

With the popularization of inexpensive, power-saving LEDs, the use of illumination in automobile interiors has become more and more frequent. This decorative multilayer molding, which is characterized by its sense of translucency and luster, is an outstanding complement to that illumination.

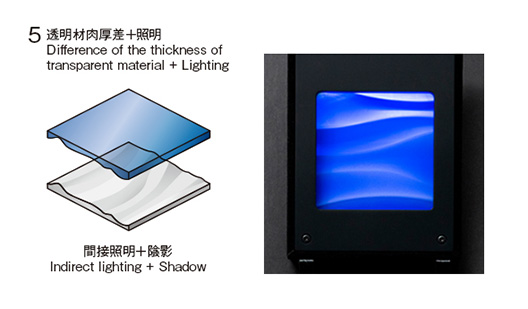

[Sample 5] has a two-layer structure whose clear surface layer has been given varying thickness and whose substate has had 3D modeling added to it.When LED is combined with this structure, shadowing not unlike that produced when indirect lighting is applied yields a dramatic effect.

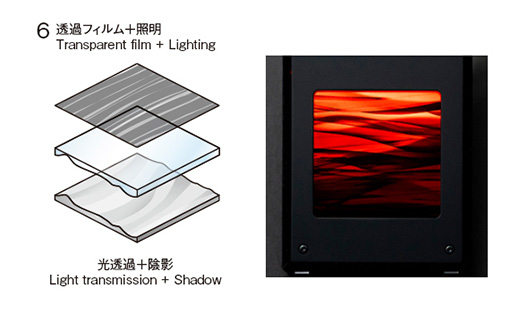

[Sample 6] is a combination of Sample 5 and a semitranslucent film applied to the top of it.In bright surroundings, the surface layer reflects considerable light, rendering the depths of the film nearly invisible. However, lighting up LED in the dark causes the modeling at the film’s depths to stand out.The aim of this proposal was to realize the effect created when the countenance of a vehicle’s interior changes completely between day and night.

Diverse automobile interior with the application of decorative multilayer molding

The decorative multilayer molding, which is characterized by its sense of translucency and luster, is an outstanding complement to that illumination.

Combination with resin and film contains solid molding and depth.

When lights are paired with this construction, the resulting shadow, which looks like the product of indirect light, yields a dramatic effect.

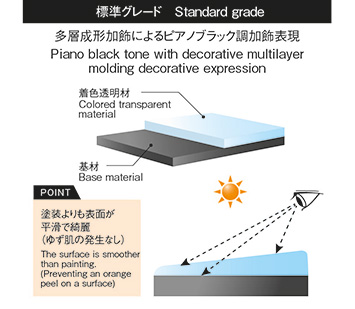

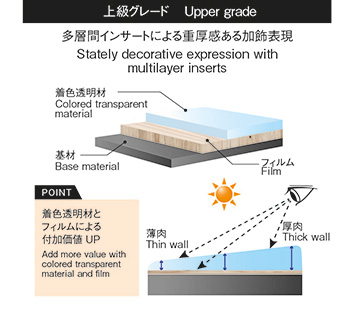

Varieties according to grade are possible with identical dies

With the application of decorative multilayer molding, it is also possible to ready varieties for different grades of the same car model, using identical dies. Accommodating increasingly-diversified user needs while curbing costs helps make finished automobiles more competitive.

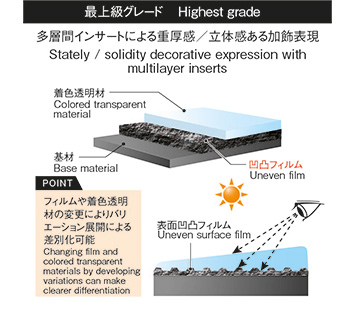

The below figure is an example of our proposed uses of this technology. Using colored translucent material with differing plate thicknesses, we supply decorative elements with a piano black tone. Compared to coating-based decoration, the surface in this example is even and smooth, with no risk of “orange peel”-like unevenness arising. When dealing with upper-grade specifications, to give an example, we place film with a wood grain tone between the substrates and translucent materials. This enhances both the sense of depth and the grade of the luxury interior containing these elements. For our topmost grade, we add solid molding to three layers that include film. This creates a luxurious relaxation space that displays a plethora of expression depending on how light hits the elements. When designs using this technology are put together with minor changes in mind from the get-go, they can be used to enhance the marketability of products without the need for considerable additional investment.

MORIROKU TECHNOLOGY

MORIROKU TECHNOLOGY

Presenting a luxurious look at a comparable cost to coating

Presenting a luxurious look at a comparable cost to coating