Products

Introducing the technologies of Moriroku Technology and its major products.

Technology introduction

The "CASE" wave (Connected, Autonomous, Shared, Electric) that is inundating the automobile industry is drastically transforming the way business is done while engulfing even peripheral industries, and with that car needs are growing ever more complex. Against this backdrop, Moriroku Technology maintains its unstinting effort to meet customer's and society's expectations. Please take a look at the examples of its diverse technologies.

Functional technologies

Functions support a safe, secure, and user-friendly space

Console

Moriroku's proprietary technology, which exploits the properties of resin, helps in everything from the development to the manufacture of streamlined and lightweight consoles. Functional assurance is checked at Moriroku and its technology is being adopted in a wide range of small to large vehicle models and even SUVs.

Click here for information on technology

Click here for information on technology

Instrument panel

Seamless tear-line machining instrument panels and peripheral parts (glove compartments, panels, air vents, air ducts, etc.) are designed and developed collectively, and can be supplied as an instrument panel module.

Click here for information on technology

Click here for information on technology

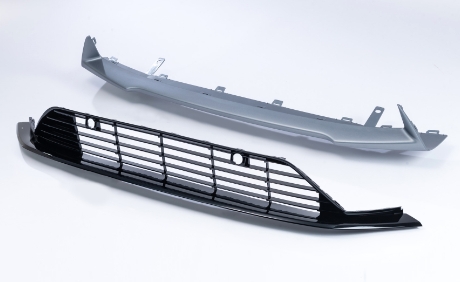

Large exterior parts

We develop and manufacture large coated parts such as radiator grills and roof spoilers, as well as general exterior resin parts including cowl louvers. Moriroku Technology's parts are used in the car's face, exterior design, and other parts.

Click here for information on technology

Click here for information on technology

"Decorative"technology

Producing an interior that is comfortable and cozy

Injection molding technology

Multilayer molding

We can mold multiple materials within the same mold and manufacture it as a decorative molded product.

Click here for information on technology

Click here for information on technology

Coating technology

Interior coating

We help to improve the interior parts' texture by applying a piano black coating that appears jet black and a very bright coating that looks like metal.

In-mold decorative technology

Film molding

This is a technique wherein a film is inserted in a mold and injection molding is simultaneously performed. An alternative technique is to insert a preformed film in a mold and perform resin injection molding.

Click here for information on technology

Click here for information on technology

Secondary processing with decorative technology

Vacuum molding technology

This technology draws a warmed sheet material into a vacuum through suction and bonds it to a resin product.

Hot stamping method

This is a technique that transfers foil with metal or ink attached to it to the resin product's surface.

Click here for information on technology

Click here for information on technology

Product introduction

Moriroku Technology offers a wide range of products, from resin molded parts for four-wheeled vehicles to exterior parts for two-wheeled vehicles, as well as functional parts. An idea that originated from the development of solutions based on market needs became a model that we have refined through trial production and testing, and is now mass produced as products in factories around the world according to the same quality standards.

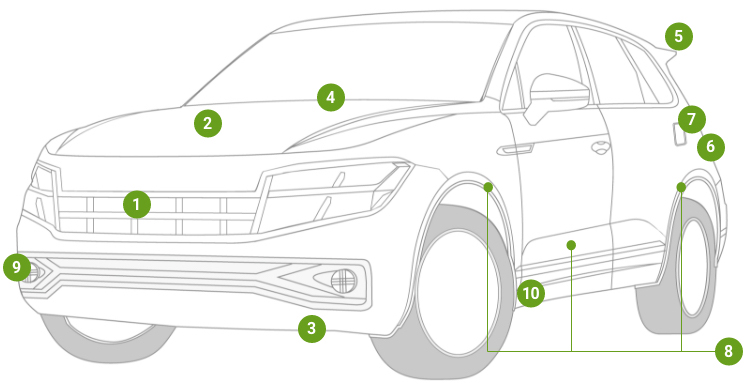

Exterior parts for four-wheeled vehicles

Main products

-

Radiator grill

-

Engine cover

-

Bumper lower garnish

-

Cowl louver

-

Roof spoiler

-

Back door garnish

-

Fuel filler lid

-

Door/Fender protector

-

Fog lamp cover

-

Side sill cover

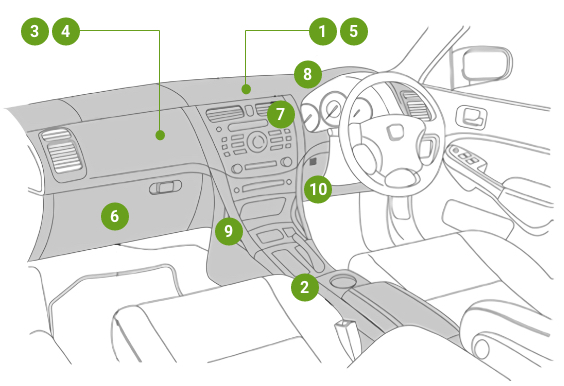

Interior parts for four-wheeled vehicles

Main products

-

Instrument panel

-

Center console

-

Interior knotty panel

(film material) -

Interior knotty panel

(leather-like surface material) -

Instrument panel duct

-

Glove compartment

-

Center cluster & ventilator

-

Meter visor

-

Center lower cover

-

Instrument panel lower cover

(driver side)

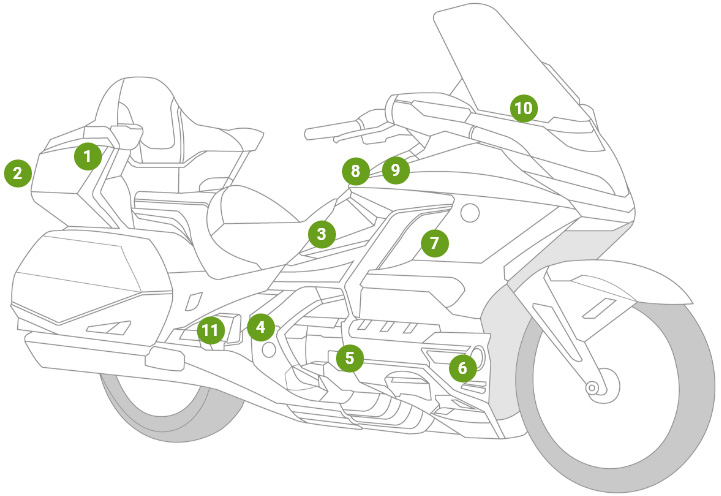

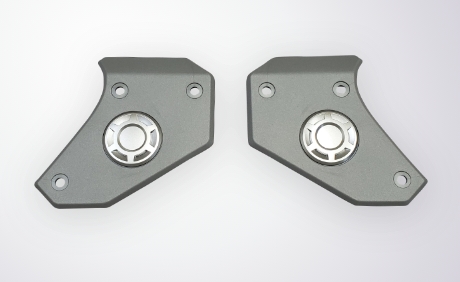

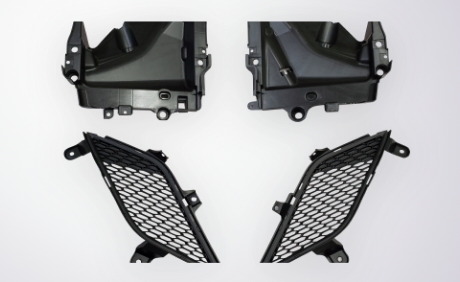

Two-wheeled vehicle parts

Main products

-

Trunk hinge

-

Rear center cover

-

Shelter cover

-

Pivot panel cover

-

Engine cover

-

Fog cover

-

Radiator grill

-

Fuel filler opening

-

Speaker cover

-

Window screen stay

-

Step cover

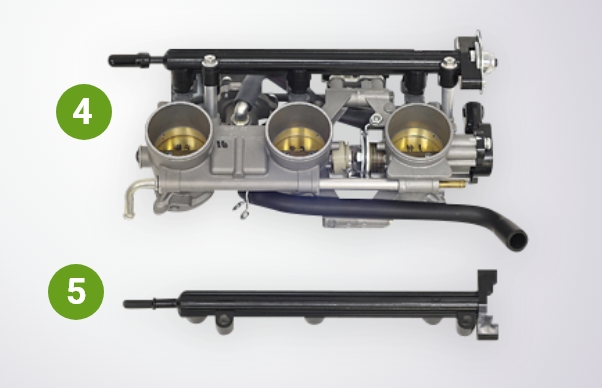

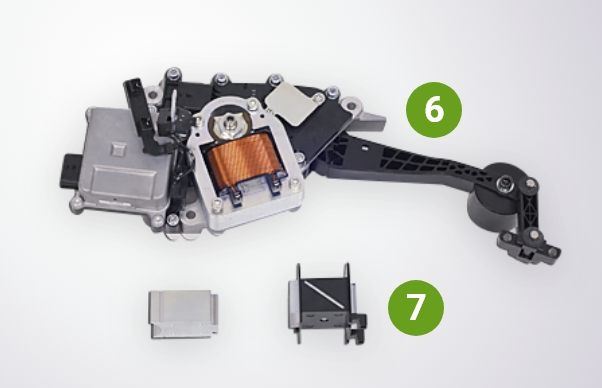

High-performance parts

Main products

Fuel system functional component

Carburetor pump (for two-wheelers)

- ①Carburetor pump (for two-wheelers)

- ②Float

- ③Float (different type)

Fuel system functional component

Throttle body pump (for general two-wheelers)

- ④Fuel system functional component

Throttle body pump (for general two-wheelers) - ⑤Delivery pipe

Electronic control

Accelerator pedal module (for four-wheelers)

- ⑥Electronically controlled accelerator pedal module

(for four-wheelers) - ⑦Coil bobbin

MORIROKU TECHNOLOGY

MORIROKU TECHNOLOGY

Technology introduction

Technology introduction