A new partnership with Volkswagen

Moriroku takes its international business to new heights in Mexico

While Moriroku had established operations in various countries in partnership with Honda, Mexico was the first country it ventured into independently in pursuit of new business opportunities. Before long, Moriroku successfully concluded an agreement to supply parts to Volkswagen's auto plant, which is one of the largest in the country. Faced with a new customer, location, and technical challenges, Moriroku's project team worked together to pave the way to success.

Moriroku's first big challenge after launching operations in Mexico

Moriroku first entered the Mexican market in 2012 when it established Moriroku Technology De Mexico S.A. De C.V. Its strategic goal was to attract orders from manufacturers besides its main business partner, Honda Motor Company. Eventually Moriroku was given an opportunity to supply parts to Volkswagen, which was planning to produce the next model of its popular Tiguan in Mexico a few years later. Needless to say, winning this order would be very important for the future of the Moriroku Group's international expansion.

In March 2015, Volkswagen announced it would invest about one billion U.S. dollars to expand its Puebla Plant in preparation for manufacturing the new Tiguan model. As one of the largest auto assembly plants in the Volkswagen Group, the Puebla Plant was producing the Jetta, Beetle and other models for export to Europe and North and South America.

While Moriroku was a candidate to supply auto parts to Volkswagen, it had never manufactured parts for a non-Japanese automaker. Therefore, the project team began studying successful techniques for doing business with German companies, and worked with an experienced consultant to prepare for bidding and negotiations. While everything was completely new, the team kept moving forward one step at a time, receiving assistance from employees with English language skills. Before it could even submit a bid, Moriroku was assessed by Volkswagen for its ability to develop parts, and given one year to show that it could serve as a dependable supplier. Soon after, the team created a 100-page document explaining Moriroku's quality assurance, covering all processes from product design through to mass production and delivery, and gave a presentation to Volkswagen's representatives. Various challenges followed, but Moriroku eventually received its first order for parts within a year. Despite its initial inexperience, the project team made steady progress and opened the door for Moriroku's future in Mexico.

Comment from a project team leader"While Mexico is a new country for the Moriroku Group, our team believed we could win this bid. Using English, German, and Spanish, we worked very hard together to achieve success." Hiromi Morimoto

Overcoming challenges and demonstrating leading capabilities

Moriroku eventually won the order, but many new hurdles were on the way. Volkswagen's approach to quality and product design was based on European market standards, which are very different from those in Japan. Therefore, step by step, Moriroku had to learn about differences in specifications, precision requirements, and reasons for selecting materials and manufacturing methods.

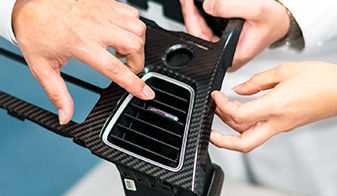

Among the major differences was a method of molding air vents, which required a technology that Moriroku was unfamiliar with. Volkswagen's air vents were made with an advanced automated molding method that is unique to Europe, and the molds were produced only in Germany. Therefore, despite having previously assigned a mold manufacturer in Japan, Moriroku decided to purchase the molds from the German supplier after checking its molds and manufacturing machinery onsite.

After overcoming such challenges, Moriroku developed high-quality parts that passed Volkswagen's strict inspections, and supplied them for the new Tiguan. The successful adoption of these parts demonstrated Moriroku's ability to deliver high-quality and cost-competitive auto parts in the global market.

Comment from a project team account manager"Starting from scratch was more difficult than I expected, but our efforts led to a major breakthrough for Moriroku in Mexico." Naotaka Ohta

Moriroku's spirit of challenge leads to new opportunities

Moriroku secured orders from a customer that was not only completely new but also a leading global automaker, and then supplied its products according to strict specifications. This was not a smooth path, however, as the company's inexperienced project team had to devise optimum solutions and make tough decisions amid risks and uncertainties. Nevertheless, the team overcame these difficulties because its members were strongly determined to win over the customer with unrivalled products and raise Moriroku's presence in a new market. This spirit of challenge has been passed down since the company's founding and continues to drive the Moriroku Group to the present day. By gaining a foothold for new businesses, as it accomplished in Mexico, the Moriroku Group will strive to play a bigger role on the global stage as a proven international enterprise.

Employees of Moriroku's subsidiary in MexicoAt Moriroku Technology De Mexico S.A. De C.V., employees worked hard together to ensure high quality and establish a safe production system using advanced designs.

More about us

Next three stories

Contact us

MORIROKU HOLDINGS

MORIROKU HOLDINGS