Moriroku Technology's manufacturing technology

Our strength lies in our integrated system that handles everything from product planning and design to prototype and testing, mass production, as well as mold design, production, and adjustments required for these steps. With this system we can reliably meet customer needs and provide products that fully meet customers' quality, cost, and delivery (QCD) needs.

Development plan

Review specifications and designs of molds, jigs, and equipment used in production

- Create mold development plan

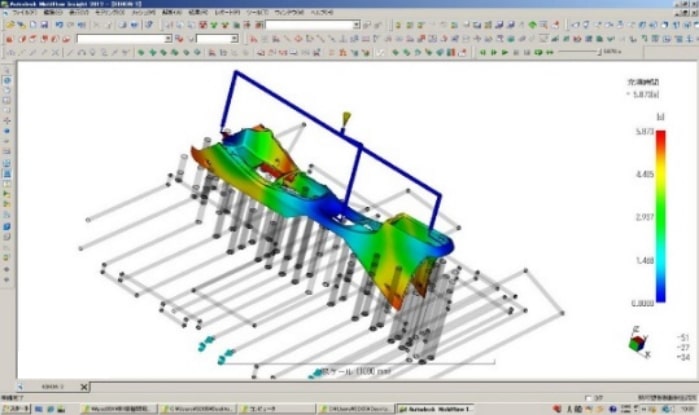

- Perform flow analysis

- Create jig and equipment development plan

- Review dedicated jigs and equipment

Create specifications

Create and design specifications for molds, jigs, and equipment, and reflect them in actual molds and drawings

- Create mold specifications

- Check molds and molding on site

- Create jig and equipment specifications

- Check jig and equipment drawings

Confirming that the mold can be formed according to specification

Mold-making process

1. Design/CAM

2. Machining

3. Finish

Also see the following page.

Verification

Verify the accuracy of molds, jigs, and equipment and determine if there are any problems

- Perform inspection tool measurement and verification of actual vehicles

- Measure molded products with a three-dimensional measuring machine

- Verify jigs and equipment

- Instruct how to modify jigs and equipment

Checking the accuracy of a molded product with a non-contact laser

Assessing whether the jigs and equipment produced have defects

Start mass production

Transfer molds, jigs, and equipment deemed to be mass-producible to the factory and start mass production

- Transfer molds

- Transfer jigs and equipment

- Provide technical guidance for mass production and overseas bases

- Start mass production

MORIROKU TECHNOLOGY

MORIROKU TECHNOLOGY