What are the strengths of the company’s Resin-Treated Products Business?

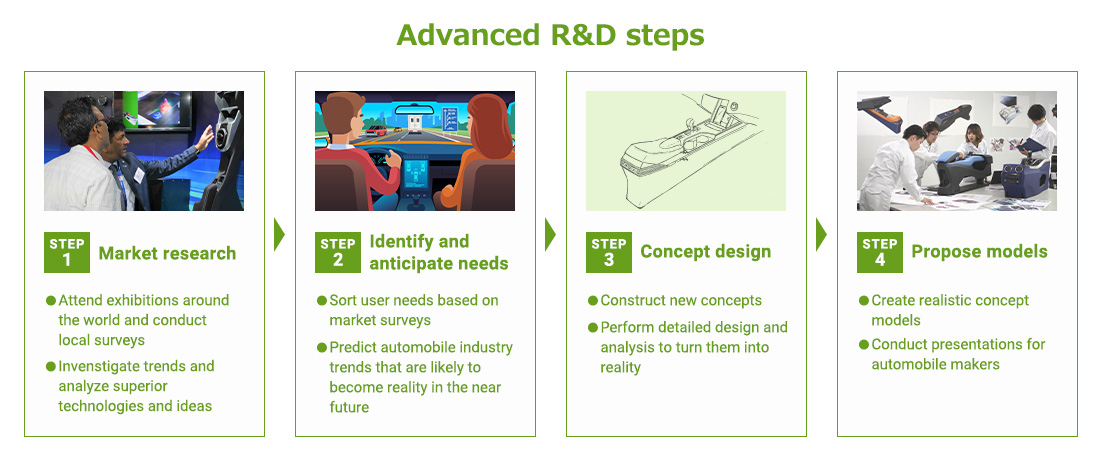

Proposal capability based on advanced development

With R&D sites in Japan, the US, China and Thailand, the Moriroku Group grasps local needs through those four headquarters throughout the world, plans and develops ideal designs and functions for “the cars of tomorrow,” and proposes them to automobile manufacturers.

Rather than produce what it is ordered to by those manufacturers, the Moriroku Group makes proposals from its own end as it proceeds to bring forth value for cars. This is what has enabled us to win over customer confidence as a supplier.

Bonds of trust with Honda that have lasted years

Over 90% of sales under our Resin-Treated Products Business are accounted for by products sold to Honda Motor Co., Ltd. (“Honda” below). More or less all of the vehicle models that Honda releases to the market globally contain resin parts by the Moriroku Group.

Our experience of becoming involved in the process of creating the Honda Super Cub from parts development to mass-production and helping to make it a success back in 1958 formed the foundation for the bonds of trust between Honda and the Moriroku Group that endure today.

-

Succeeded in using resin to produce front cover of Honda Super Cub -

The console in the Honda Accord continues to evolve in line with the times

Future potential for making contributions to CASE

The automobile industry is approaching a major transformative period, the kind that only occurs once every 100 years, that is referred to as “CASE.”

As the rapid shift to EV continues to progress, resin parts, which are lighter in specific gravity than steel and easier to process, hold considerable potential. Moreover, as automatic driving evolves further, needs to make automobile interiors more like living rooms will also grow alongside the desire to make them into more relaxed environments. We at the Moriroku Group believe that both of these developments have the potential to become major opportunities for us. Going forward, using our abundance of knowledge of resin-forming, we will continue to propose new interior and exterior parts and support the evolution of automobiles.

-

Next-generation consoles for automatic driving and electrification -

A resin tailgate with a 35% lighter weight compared to its metal counterpart

Back to the index of "To all individual investors"