R & D

Shaping the Future of Mobility.

As a specialized manufacturer of resin molded parts for automobiles, Moriroku has built an in-house integrated system that covers everything from planning to mass production. In the R & D department, in addition to global needs, we catch local needs and promote proposal-type development. Utilizing cutting-edge technology, we are embodying the "future of cars." In addition, at production bases around the world, we have refined highly efficient production lines to realize QCD that meets the needs of each market.

Proposing a New Interior Value that Combines Comfort and Design - New Value Air Vent

Moriroku Group adds new value to the cabin space by dividing and diffusing the airflow and drawing the distributed air into the central area between the two airflows to create a soft and comfortable air-conditioned breeze.

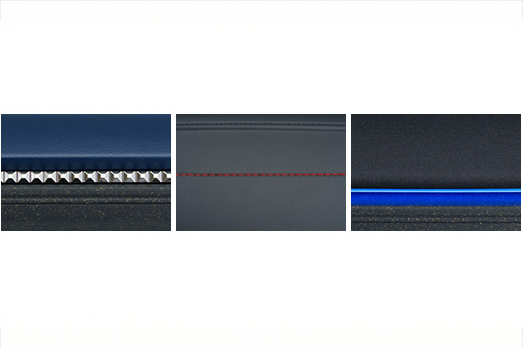

Decoration to Replace Plating & Painting by High Extension, Colorable, Light Transmittable - Hot Stamp Decoration

Moriroku Group has developed a highly extensible foil and a proprietary construction method that effectively adheres to the foil. This unique method improves the design of automobile interior and exterior parts.

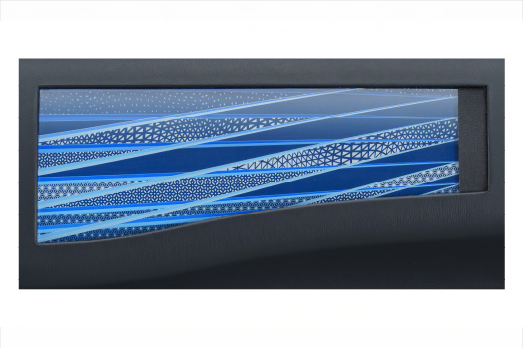

Excellent Harmony with Ambient Lighting Combines Design and Rationalization - Multi-Layer Molding

Moriroku Group has developed a technology to sandwich a printed film between the surface layer and the base material layer using a unique mold concept, which has increased the variation of multilayer decoration.

Paintable, Flexible, Transmittable, Next-Generation Photovoltaic Technology - Photovoltaic Ink Painting

Moriroku Group is researching next-generation "energy generation" to realize a carbon-neutral society. Photovoltaic Ink" has superior ink processability, flexibility, and transparency compared to conventional silicon-based solar panels.

Reducing Petroleum-Derived Materials & Express the Value of Plant-Derived Materials - Sustainable Materials

The Moriroku Group applies environmentally friendly materials to decorative parts and conducts research to enable end users to realize the value of sustainable materials.

Proposal of next-generation console for automated driving and electrification. 2 WAY Living Console

Our unique technology and ingenuity in the pursuit of "how to relax" and our attention to usability and design create a comfortable living space in the car.

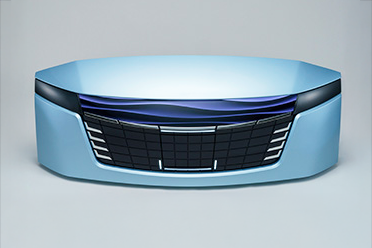

Greater possibilities allowing for broader, freer exteriors

Freed from the notion that front grilles need an engine coolant port, new exteriors in this era of EVs are exciting.

Moriroku combines technologies to stimulate the creative power of designers and turn dreams into reality. Leveraging our proven record of development, we make it possible to realize designs with a unified sense between interiors and exteriors, and offer an advanced look at the future.

Achieved lighter weights and reduced part count with resin tailgates

A challenge of ours has been to make bodies lighter in weight by substituting resin for metal. For ten-plus years, we have been conducting R&D on using resin to manufacture “back doors,” which are large parts, and have already established technology for their mass-production.

The potential for lighter weights is over 35% of preexisting weights. We are also able to considerably reduce part counts.