Contract Manufacture of Chemicals (Goko Kasei Industrial)

Contract Manufacturing of Bromination Reactions, Inorganic/Organic Synthesis Reactions, etc.

Goko Kasei Industrial Co., Ltd.

Goko Kasei Industrial Co., Ltd. (Moriroku Group company) undertakes contract manufacturing according to customer needs, including inorganic and organic synthesis reactions, bromine and halogenation reactions, reactions using strong acids, drying and mixing.

The facility will be renewed by adding a GL vessel in 2023, and in addition to conventional aqueous reactions, organic synthesis using organic solvents can also be handled.We have raw material tanks for bromine, hydrochloric acid, sulfuric acid, and caustic soda, and can handle production with large amounts of wastewater.In April 2025, a new drying building will be constructed, and drying facilities will be upgraded to prevent contamination.In April 2025, a new drying building will be constructed and equipped with a drying facility that will provide better contamination prevention.We are also developing new products utilizing our technology.

Handling a Variety of Contract Manufacturing, including Inorganic/Organic Synthesis Reactions, Bromination Reactions and more.

At Goko Kasei Industrial Co., Ltd. (a Moriroku Group company), we provide contract manufacturing services tailored to customer needs, including inorganic and organic synthesis reactions, bromination and halogenation reactions, reactions utilizing strong acids, as well as drying and mixing processes.

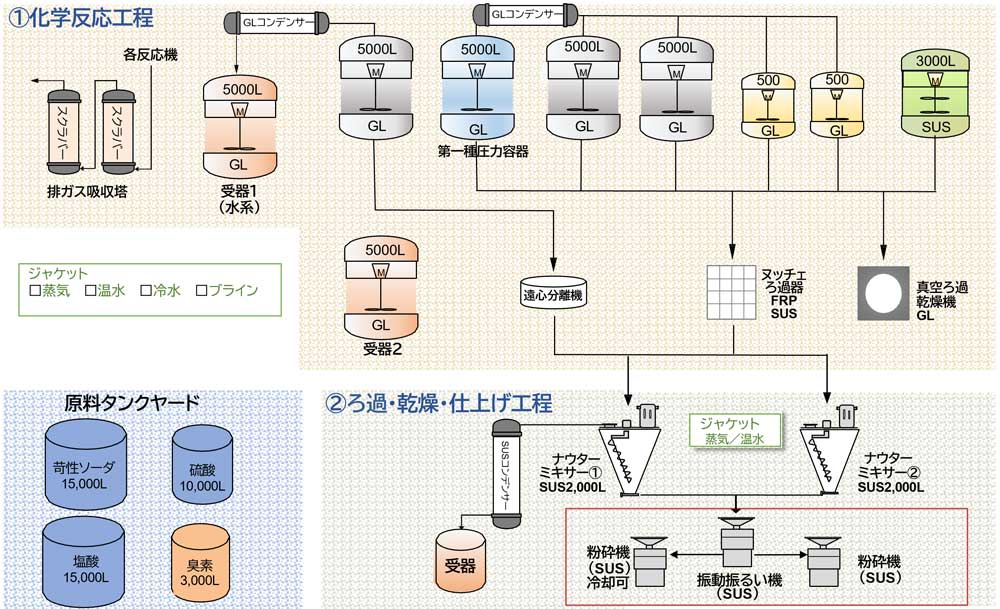

Starting in June 2023, we expanded our facilities with the addition of GL reactors and upgraded our reaction equipment. This upgrade enables us to meet broader customer needs by handling not only conventional water-based reactions but also organic synthesis using organic solvents. We offer services ranging from individual processes such as reactions, solid-liquid separation, drying, grinding, and packaging, to continuous integrated production.

Our factory is equipped with raw material tanks for bromine, hydrochloric acid, sulfuric acid, and caustic soda solutions, allowing us to manage manufacturing processes that generate large volumes of wastewater. Furthermore, starting in April 2025, we will construct a new drying facility featuring contamination-prevention measures, enhancing production efficiency.

"In addition, we have enhanced the experimental facilities and analytical instruments in our laboratory, enabling us to handle small-scale lab prototypes, process development, contract research, reagent preparation, and repackaging services. Leveraging our research and development capabilities as well as our proprietary technology, we are also expanding into the development of original products.

- Specialized Field

- Synthesis Technology

- Main Facilities/Equipment

- Factory Facilities

- Warehouses

- Laboratory Equipment

Specialized Field

-

Manufacture of chemical raw materials, industrial chemicals, electronic materials, automotive materials, agrochemical intermediates, pharmaceutical raw materials (non-GMP compliant), and natural product extracts

-

Halogenation, acid chlorination (using phosphorus trichloride, etc.), bromination, and other halogenation processes (using phosphorus trichloride, phosphorus oxychloride)

-

Processing or operations such as crystallization, filtration, drying, grinding, filling, packaging, etc.

-

Alkali treatment, hydrolysis, neutralization reaction, etc. (SUS kettle used)

-

Laboratory support: small-lot prototyping, synthesis studies, processing studies, reagent preparation, small-lot support, precision distillation, etc.

Synthesis Technology

-

Bromination

-

Acid chloride

-

Halogen addition

-

Esterification

-

Sulfonation

-

Nitration

-

Natural products extraction

-

Dehydration

-

Anhydride

-

Neutral reaction

-

Aqueous solution

-

Metal hydroxylation (oxidation)

-

Polymerization reaction (polymerization)

-

Fridel-Craft reaction

-

Vilsmeier reaction

-

NaBH4 reduction

-

Air oxidation

-

Powder mixing and drying

-

Polymer surface treatment

-

Precision distillation (lab supported)

Main Facilities/Equipment

Reaction facilities

GL kettle, SUS kettle

-

General substances - Reaction with acidic and corrosive substances

-

Capable of solvent removal and decompression concentration

-

Crystallization and slurries are possible

-

GL Reaction Kettle (5000L) -

GL Receiver and Scrubber Equipment -

GL Condenser

Drying Equipment

Nauter dryer, vacuum filtration dryer

-

Mixing of various powders

-

Capable of decompression drying of powders

-

New Drying Facility -

Nauter Dryer Lower Part -

Vacuum Filtration Dryer

Factory facilities

-

New Reaction Faciliity

Equipment Diagram

-

GL Reaction Kettle

5,000L / 3 units

GL Reaction Kettle (single pressure correspondence: No.20 tank)

5,000L / 1 unit

GL Reaction Kettle

500L / 2基

SUS Reaction Kettle (SUS316L)

3,000L / 1 unit

GL受器

5,000L / 2 units

[Annotation 1] GL reaction blade: MOLE PAW blade (manufacturer's standard type)

[Note 2] Reaction blade: Top and bottom two blades (SUS)

-

Nutche Filter (FRP)

2.1㎡ / 2 units

Nutche Filter (SUS)

2.7㎡ / 2 units, 1㎡ / 1 unit

Vacuum Filter (GL)

1㎡ / 1 unit

-

Nauter Dryer (SUS304)

2,000L / 2 units

-

Vibration fluy machine (SUS304)

2.2kW / 1 unit

Crusher (Fitzmill: SUS304)

5.5kW / 1 unit

Crusher (Power Mill: SUS304)

3.7kW / 1 unit

-

Exhaust gas cleaning tower (scrubber: FRP)

1,800L/2-row type (caustic soda solution, water circulation)

VOC treatment equipment (SUS304: activated carbon)

30 L / 1 unit

Brine chiller (-5°C)

11RT / 1 unit

Chilled water chiller (7°C)

18RT / 1 unit

-

Bromine (Br)

3,000L / 1 unit

Sulfuric acid

10,000L / 1基

Hydrochloric acid

15,000L / 1基

Caustic soda (25% aqueous solution)

15,000L / 1 unit

-

Raw Material Tanks (caustic soda, sulfuric acid, hydrochloric acid) -

Bromine Tank

-

Warehouses

-

Hazardous Materials Class 4 Warehouse

-

Hazardous material class 4 warehouse (fireproof)

-

Hazardous Materials Class 5 Warehouse

-

Hazardous Materials Class 4 Warehouse -

Hazardous Materials Class 5 Warehouse

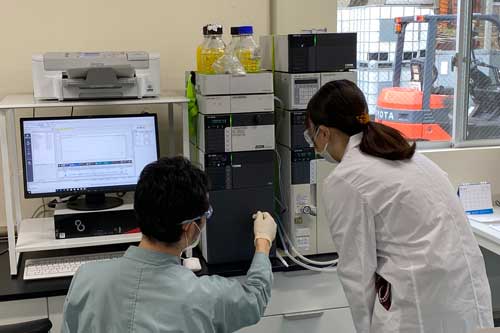

Laboratory Equipment

At Goko Kasei Industrial, we facilitate smooth transition to pilot-scale production in our factory for new contract manufacturing projects by tracing customer recipes and evaluating process development. This support aims for early-stage mass production transfer. We also offer timely instrument analysis and reaction monitoring for process and product analysis in both laboratory and pilot-scale trials.

In addition to supporting new contract projects, we also undertake sample manufacturing, research and development support, trial preparation, small-lot packaging, precision distillation, and other services at a lab-compatible level.

-

-

25mL to 5L glass flask

-

500mL/1L Reactor (miniature GL reaction vessel)

-

1L glass reaction filtration system (GL vacuum filtration dryer)

-

-

-

1L rotary evaporator

-

Precision distillation equipment

-

-

-

Vacuum specimen dryer (decompression drying: room temperature to 200°C)

-

Desiccator (atmospheric pressure drying: room temperature)

-

High-temperature incubator (oven: room temperature to 250°C)

-

Electric furnace (100-1,150°C)

-

-

HPLC

[Shimadzu LC-20 (UV, RID: Autosampler)

GC

[Shimadzu GC-2014 (FID: Capillary)

UV-Vis

[Shimadzu UV-1280 (190-1100nm)

FT-IR

[Thermo Scientific Nicolet Summit LITE(8,000~350㎝-1)]

NMR (60MHz)

[Nanalysis NMReady 60e]

Karl Fischer moisture titrator

[KEM MKV-710]

Potentiometric autotitrator

[KEM AT-710]

Melting point measuring instrument

[Yamato Scientific MP-21]

pH meter

[東興化学 TPX-999、メトラートレド FiveGO]

Digital Viscometer

[ATAGO VISCO]

Apparent Viscosity Measuring Instrument

[RIGOSHA&CO SOD]

Simple viscometer

[RION VT-04E]

Marron Teste

[Yasuda No156]

-

Homogenizer

[Primix.]

Centrifuge

[KUBOTA Table Top 4000]

[Note: Analysis and laboratory medium-volume prototyping, etc., which cannot be handled by Gokoh Kasei, are handled by an outside organization.

Related Links

-

Fine chemical Field

With "manufacturing" as our theme, we propose optimal functional products and manufacturing processes.

-

Medical Field

In addition to the sale of raw materials to intermediates for pharmaceuticals and agrochemicals and contract synthesis of chemicals, we also provide materials related to medical products such as medical films.

-

Functional materials Field

Functional materials used in a variety of industries, including automotive, electronics, construction, and medical, help improve product performance and reduce environmental impact.

-

Goko Kako Industry Company Profile & Google Map

For a company profile and map of Goko Chemical Industryh Co., Ltd. please visit our global network.