Moriroku's Quality Assurance

Quality assurance policy

Taking advantage of Moriroku's various test facilities, we implement proof of principle through quality assessments and reliability testing. We seek to further raise customer satisfaction by building a quality assurance system for the future to find and carry out additional methods of improvement, and ways to deal with potential problems.

Quality assurance system

With bases all over the world, we are conducting "faster and better" product development and stabilizing market quality by using our ability to promptly respond to customer needs. Also, with our various testing facilities, we are building a quality assurance system for the future with the aim of further improving customer satisfaction based on proof of principle through quality assessments and reliability testing.

From the standpoint of quality stabilization, we are evolving our technology and quality assurance system, and expanding it globally to ensure that we deliver the same quality worldwide.

Example of Testing Facilities

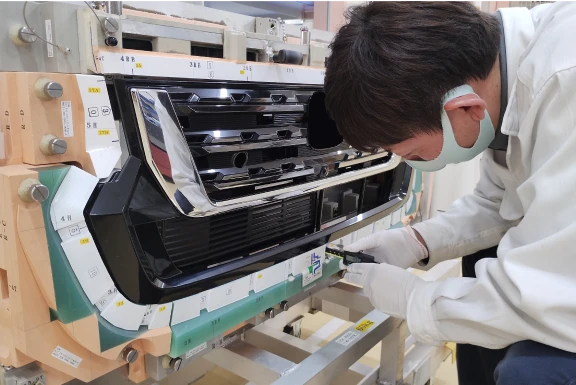

Operation Durability Robot

We use motion robots to replicate human behavior when testing products that sometimes require thousands of cycles of endurance.

The precise repetition of movements maximizes the accuracy of evaluation while reducing the burden on humans.

Air Leaking Test Machine

We reproduce the airflow of a vehicle's air conditioner and evaluate the sealing performance of the vent (the part attached to the air outlet).

Using highly sensitive sensors and smoke, we identify air leaks and provide feedback to relevant departments to improve product quality.

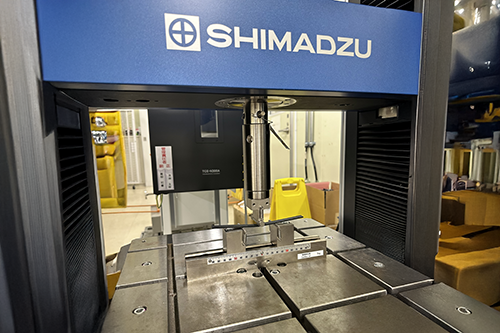

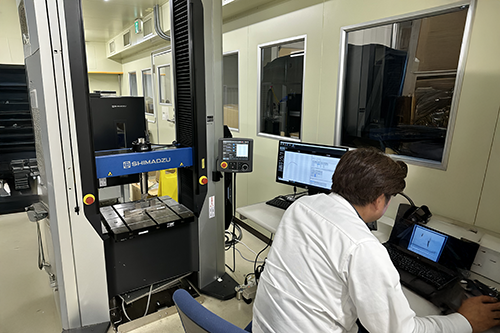

Tensile and Compression Test Machine

We evaluate the strength and rigidity of products by applying the required loads for each products.

This is used not only for production parts testing, but also for product under development, including verification and analysis of physical properties in material development.

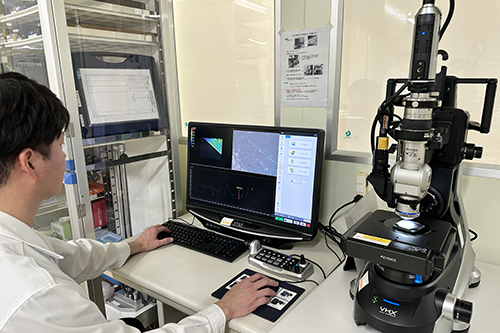

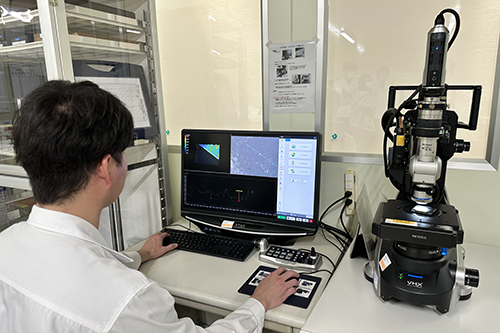

Digital Micro Scope

Using optical lenses and imaging elements, we inspect the surface after testing. Surface images can sometimes provide clues to solving problems.

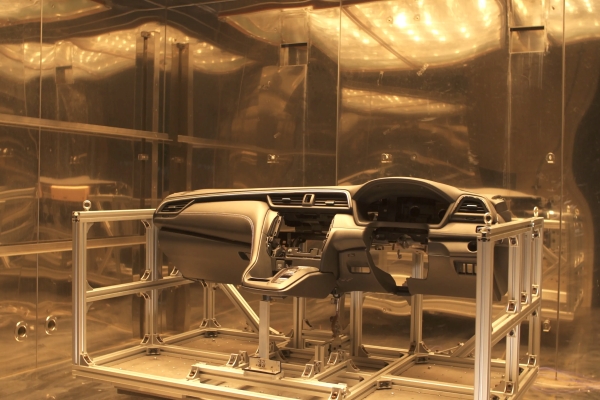

Large Scale Vibration Machine with Constant Temperature Chamber

Tests are conducted assuming all kinds of vehicle driving conditions.

We reproduce high and low temperature environments in a chamber and apply vibration to evaluate vibration resistance and the occurrence of abnormal noise.