Moriroku's Production Engineering

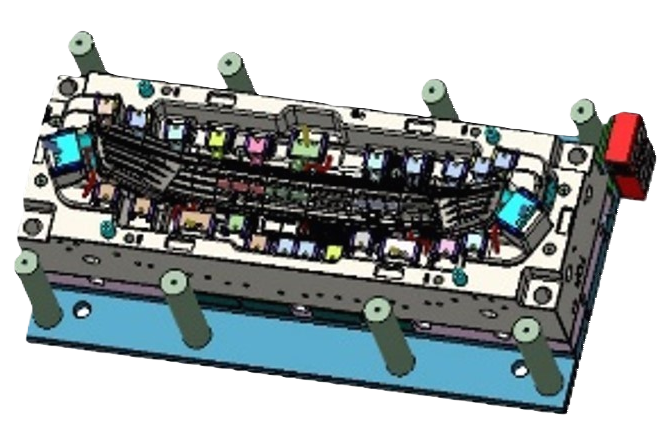

We leverage our extensive expertise in mold making and product precision assurance to ensure the highest levels of accuracy for our customers. This commitment to precision allows us to meet the stringent accuracy requirements of our clients at every stage of their development.

Development Plan

Planning and project management to keep the customer's schedule

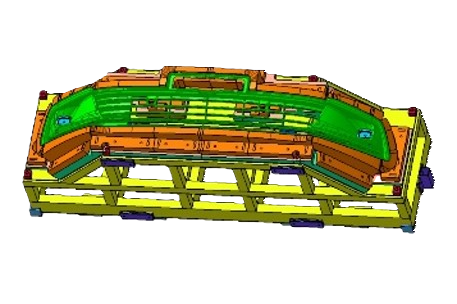

Review specifications and designs of molds, JIGs, and equipment used in production

-

Mold development plan and investigation

-

Checking Fixture plan and investigation

-

Dedicated JIGs and equipment plan and investigation

Create specifications

Planning and project management to keep the customer's schedule

Create and design specifications for molds, JIGs, and equipment, and reflect them in actual molds and drawings

-

Create mold specifications

-

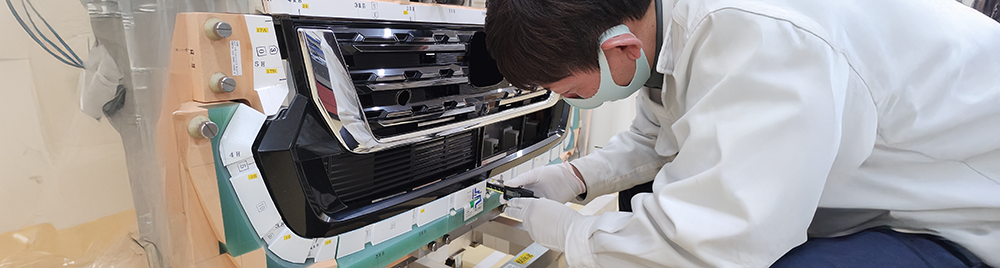

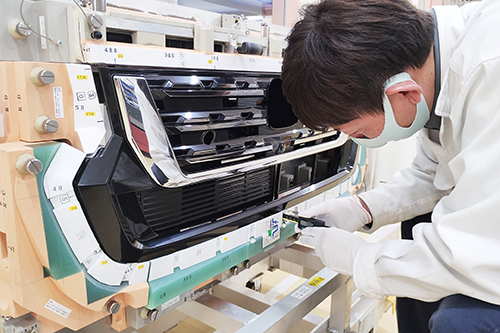

Check molds and molding on site

-

Create JIG and equipment specifications

-

Check JIG and equipment drawings

Verification

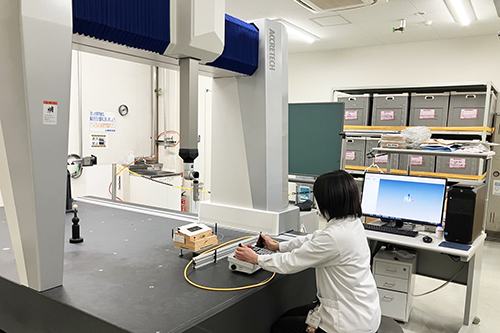

3D measurement guarantees part accuracy at the 1/100 level

Verify the accuracy of dies, JIGs and equipment, and determine the parts accuracy.

Verify the alignment of products mounted on vehicles at the customer's plant.

-

Inspection tool measurement/Vehicle verification

-

3D measuring machine measurement of injection parts

-

Verify JIG and equipment

-

Instruct JIG and equipment modification

Mass Production

Improving product precision globally by sharing technology

Transfer molds, JIGs, and equipment deemed to be mass-producible to the factory and start mass production.

Skilled engineers are stationed at our overseas production plant to complete development locally and provide training for local engineers.

We also dispatch engineers from Japan to ensure stable production.

-

Transfer molds

-

Transfer JIG and equipment

-

Technical guidance for mass production and overseas plant

-

Start of production