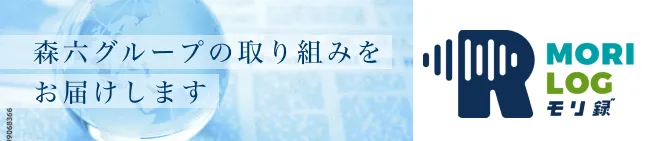

EV grille

Greater possibilities allowing for broader, freer exteriors

Freed from the notion that front grilles need an engine coolant port, new exteriors in this era of EVs are exciting.

Moriroku combines technologies to stimulate the creative power of designers and turn dreams into reality. Leveraging our proven record of development, we make it possible to realize designs with a unified sense between interiors and exteriors, and offer an advanced look at the future.

- Applying multilayer molding to exteriors

- A charging lid whose presence is emphasized only when it has to be

- The effective accent that hot stamping provides

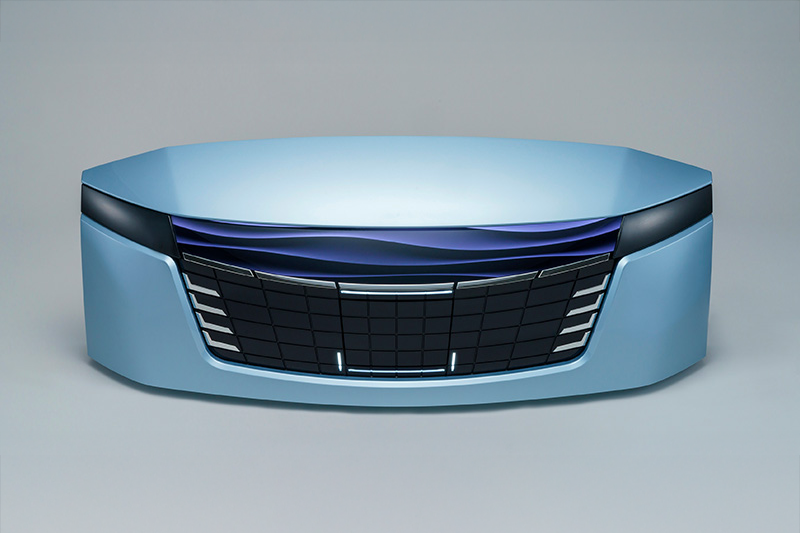

Applying multilayer molding to exteriors

By applying Moriroku's vaunted multilayer molding technology to exteriors, it is possible to add a new, unprecedented accent to exterior design.

Highquality designs accompanied by a sense of depth and solidity together with a brilliant, dazzling surface produce a feeling of specialness that befits the high price point of EVs. Combining this with uneven modeling, decorative films and even lighting technology makes infinite design variations possible.

Naturally, We can also propose front grilles and bumpers as a package set.

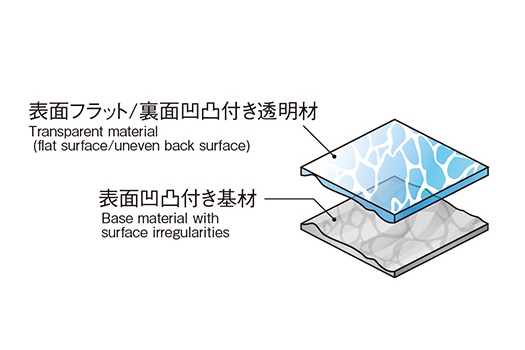

A charging lid whose presence is emphasized only when it has to be

With EVs, there is no longer a need for a large opening grille to cool down the engine room. Conversely, a lid for charging purposes has to be placed. Ideally, you would want that lid to firmly stand out and guide you so that you know exactly how to charge the vehicle, but also want it to be muted and blend in naturally with the design of the EV when not charging the vehicle. Both requests, excessive as they may seem, can be simultaneously realized.

Keeping the partition of the lid's opening area concealed within the latticed design of the multilayer transparent surface makes it possible to realize a unified design. Furthermore, because the grille area on the outer perimeter gives off light in the shape of a line, the location of the lid can be identified with ease.

This idea is one that only Moriroku, with its record of mass-producing both front grilles and charging lids, can propose.

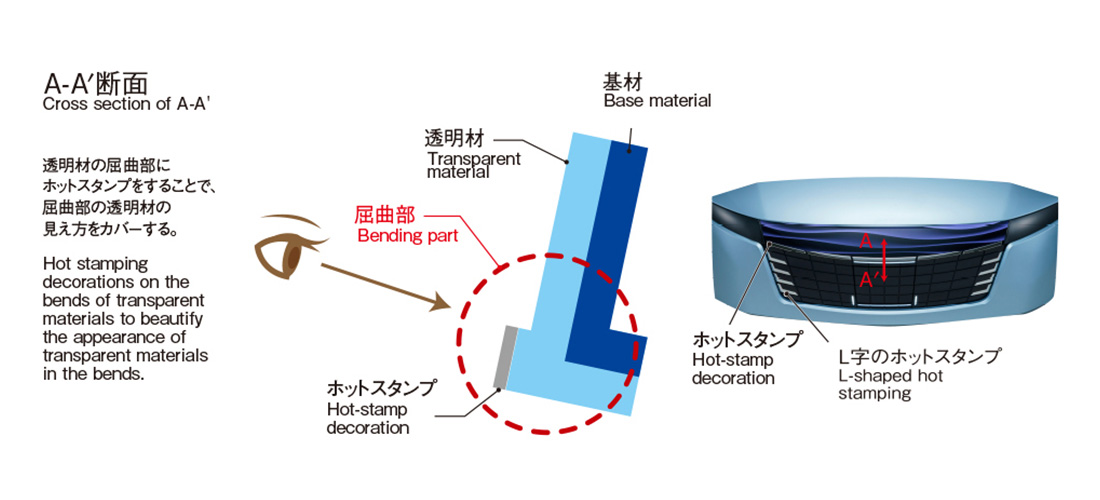

The effective accent that hot stamping provides

Aiming to reduce the environmental footprint it leaves through its manufacturing processes, Moriroku is currently pursuing the practical application of technology to replace metal plating and vapor deposition.

Not only is the hot stamp process easy on the environment and the human body, but it also has the advantage of being a useful way to effectively decorate just the target area. Like actual "stamps," this process can be used to line up elements with advanced designability or even to hide bends or end surfaces that you would rather not bring to others' attention (patent application completed).

Together with automobile manufacturers, we will create designs that leverage the attributes of hot stamping rather than simply replacing the metalplated areas as was originally practiced.