Outer Panel Resinification

Achieved lighter weights and reduced part count with resin tailgates

A challenge of ours has been to make bodies lighter in weight by substituting resin for metal.

For ten-plus years, we have been conducting R&D on using resin to manufacture “back doors,” which are large parts, and have already established technology for their mass-production.

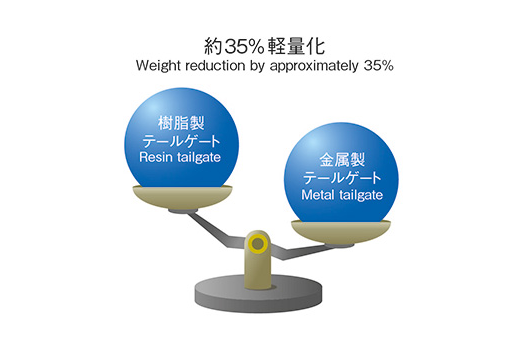

The potential for lighter weights is over 35% of preexisting weights. We are also able to considerably reduce part counts.

- Made approx. 35% more lightweight than metal framework

- Also dramatically lowered part count with integrated tailgates

- Major improvements in level of design freedom and degree of completion

Made approx. 35% more lightweight than metal framework

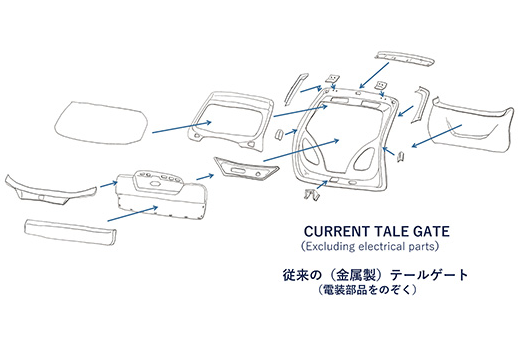

Generally, preexisting tailgate models are fixed in place from the inner and outer sides of their metal framework using interior and exterior resin parts.

Moriroku has realized considerably lighter weights by using resin to manufacture the tailgates in full, including their framework. In one development case, after securing a similar strength with that of metal tailgates, we achieved lighter weights of roughly 35%.

In addition to helping to make the entire body more lightweight and improve fuel efficiency, manufacturing tailgates out of resin also considerably improves the ease of routine use largely by mitigating the burden upon weighing up the tailgate during loading and unloading (from approx. 15kg to 10kg or less in our development model), leading to improvement of daily usability and greater user satisfaction.

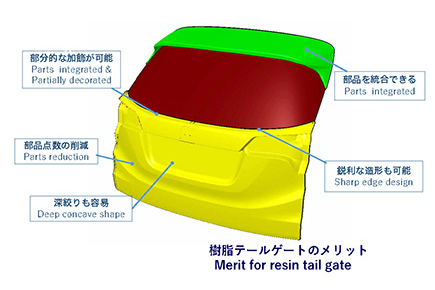

Also dramatically lowered part count with integrated tailgates

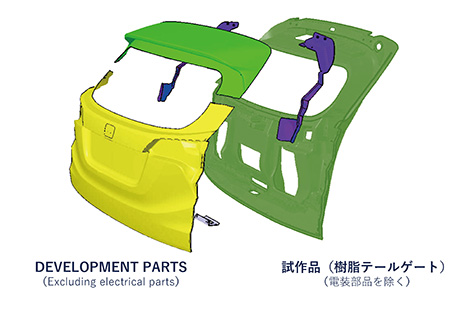

Numerous parts are concentrated around tailgates. In particular, the exterior side incorporates a large number of decorative parts that accent the design of its rear area, such as spoiler garnishes and lower garnishes. As such, dramatic reductions in part counts (to at least half) are anticipated through integrating tailgates by manufacturing them entirely out of resin.

Our record of handling a wide range of interior and exterior resin parts and even successfully mass-producing door lining is one of Moriroku’s strengths. We possess an abundance of expertise and knowledge that forms the foundation of our tailgate integration endeavors.

Major improvements in level of design freedom and degree of completion

The superiority of resin outer plates over metal outer plates is not limited to their “lightness.”

Designs that are difficult with processing steel plates (drawing and pressing), such as “acute angles” and “complex 3D structures,” can be realized with ease when resin is used. Taillights and other rear combination lamps are joined with outer plate parts perfectly without any gaps, resulting in an enhanced level of quality that extends to the details of the design.

Having built up a global record in the production of large coated exterior parts, Moriroku has fully accumulated knowledge and expertise on both strict quality testing and actual usage environments. We realize attractive exteriors just as our designers intended them to be, ones whose high grade is preserved for a long period of time.