Products

Moriroku offers a wide range of products, from resin injection parts for automotive vehicles to exterior parts for motorcycle, as well as functional parts. An idea that originated from the development of solutions based on market needs became a model that we have refined through trial production and testing, and is now mass produced as products in factories around the world according to the same quality standards.。

The "CASE" wave (Connected, Autonomous, Shared, Electric) that is inundating the automobile industry is drastically transforming the way business is done while engulfing even peripheral industries, and with that car needs are growing ever more complex. Against this backdrop, Moriroku maintains its unstinting effort to meet customer's and society's expectations. Please take a look at the examples of its diverse technologies.

Interior and exterior parts for Automotive and exterior parts for Motorcycle

-

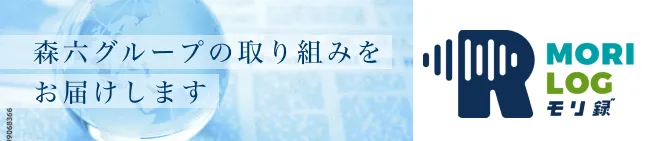

Automotive Interior Parts

Total coordination of automotive cockpits with a variety of decorative technologies. It enhances the comfort of the vehicle interior by engaging the senses of sight and touch.

-

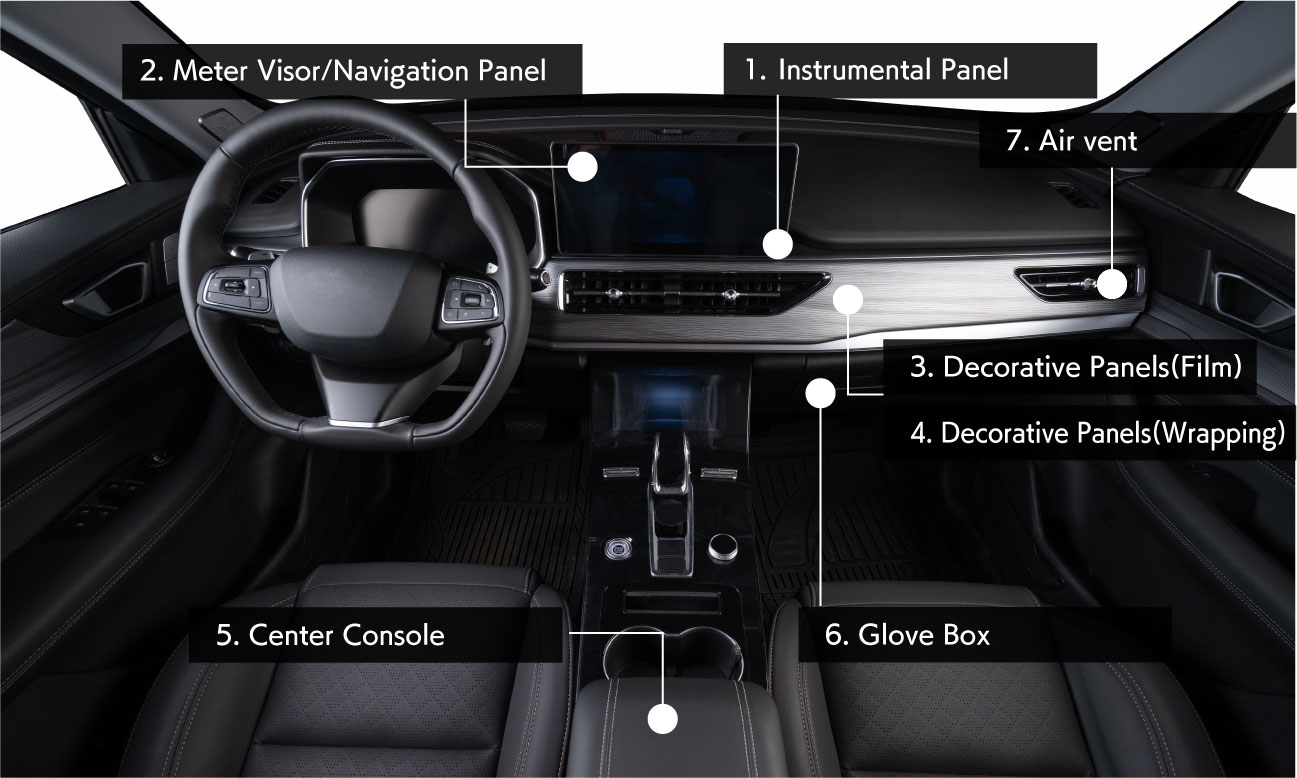

Automotive Exterior Parts

A wide range of injection machines is available for small to large parts, and high value-added is added through the application of painting and hot stamp decorations.

-

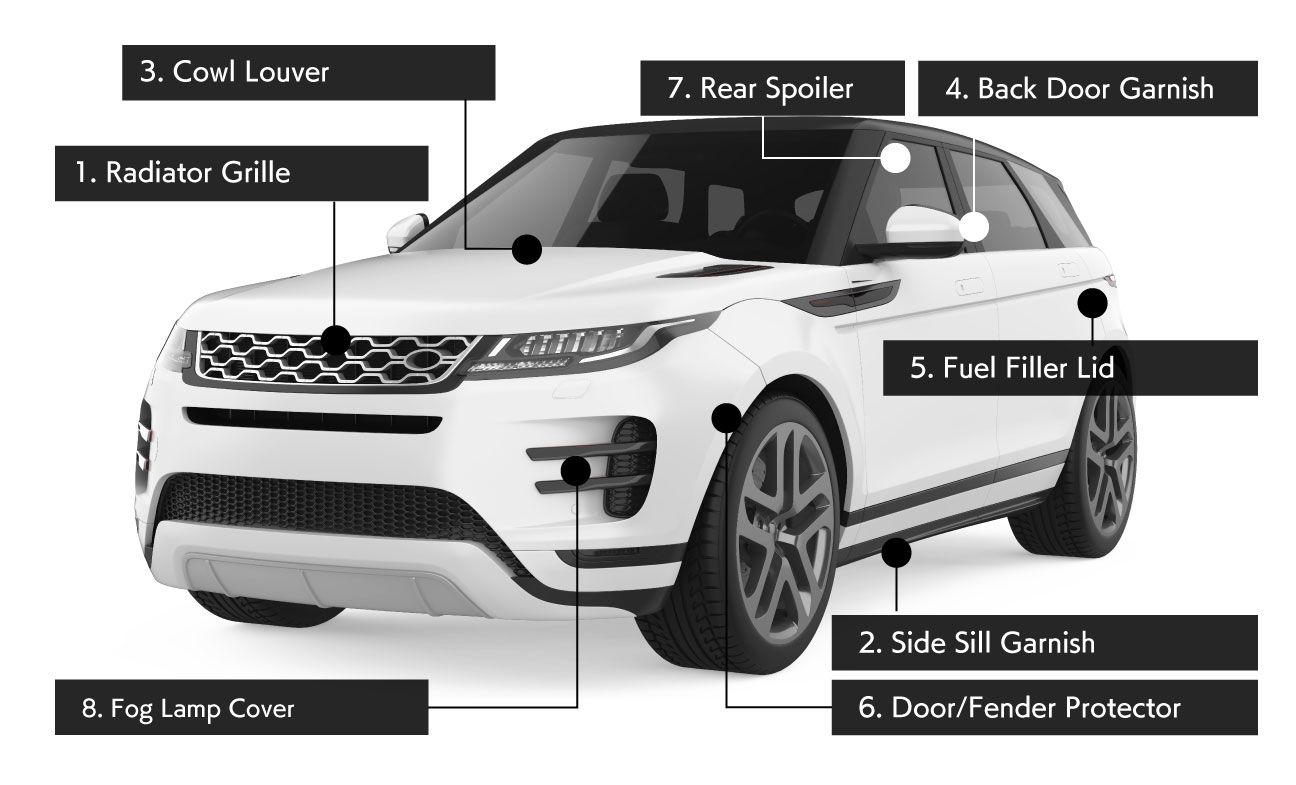

Motorcycle Exterior Parts

We produce molds based on drawings provided by automobile manufacturers, and manufacture motorcycle plastic parts and general-purpose parts by injection molding.

Moriroku's Focused Products and Technologies

-

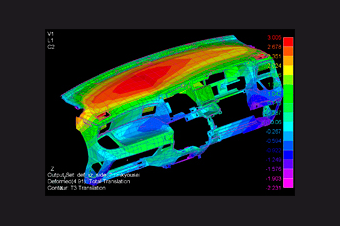

Instrument Panels

Combined with our richly-varied decoration technology, such as coating that gives off a sense of softness and warmth, we offer a total lineup of instrument panel parts.

-

Hot stamping

Moriroku offers decorative elements based on hot-stamping (hot-pressing) as a substitute technology for plating.

-

Decorative multilayer molding

We propose interiors and exteriors based on the application of decorative multilayer molding.