Connecting Electricity with Flexibility: A New Option in Conductive Rubber

"Adding a large amount of conductive filler makes rubber hard."

This long-standing belief is beginning to change.

From electronic devices and automotive components to medical sensors, conductive materials—those that carry electricity—are becoming increasingly common in our daily lives. Among them, conductive rubber is a particularly challenging material, as it must balance both flexibility and conductivity.

Traditionally, achieving sufficient conductivity required adding large amounts of conductive fillers such as carbon black or metal powders. This inevitably led to a trade-off: the rubber became harder and lost its softness.

Moriroku’s Technology Brings “Soft Conductive Rubber” to Life

Harnessing Advanced Dispersion Techniques

Moriroku has successfully unlocked the full potential of carbon nanotubes (CNTs)—known for their exceptional conductivity—through its proprietary high-dispersion technology.

This breakthrough enables high conductivity with significantly lower filler content, while preserving the inherent softness of rubber.

The resulting “soft conductive rubber” is now showing promise in applications where hardness was previously a limitation, gradually expanding the possibilities for product design.

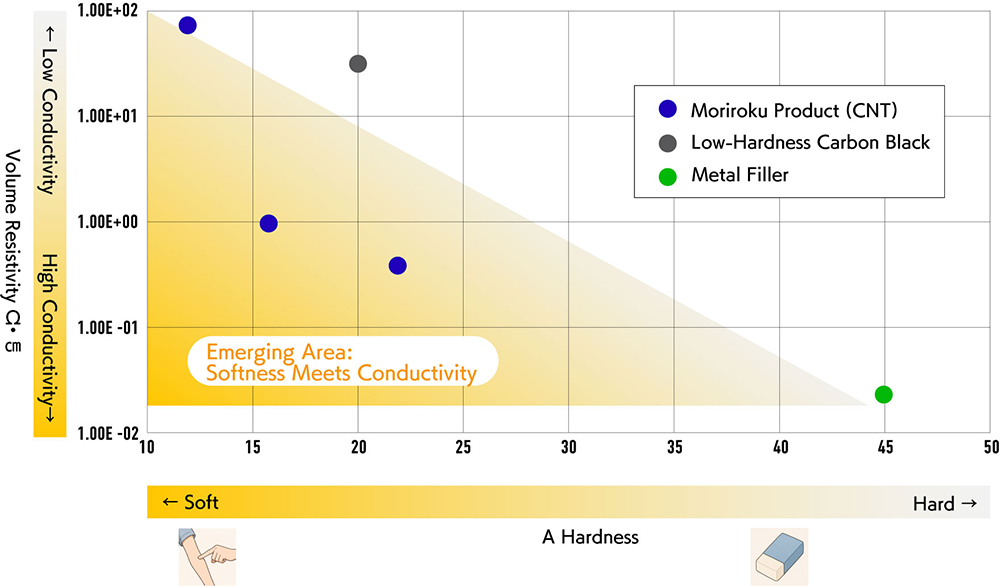

Low-Hardness Conductive Rubber: Correlation Between Volume Resistivity and Hardness

Moriroku’s newly developed soft conductive rubber achieves a rare balance between low hardness and high conductivity—something that conventional low-hardness carbon black or metal fillers have struggled to deliver.

Seamlessly Connecting Electricity — Expanding Fields of Application Automotive

Industry: Seamless Interiors & Design-Driven Innovation Contributing to seamless

vehicle interiors and enhancing aesthetic appeal.

-

Touch sensor panels and electrostatic discharge (ESD) gaskets

-

Conductive composites for EV components

-

EMI shielding materials (soft electromagnetic protection)

Medical and Wearable Devices: Gentle on the Skin, Accurate Signal Transmission

Medical & Wearable Devices: Gentle on Skin, Reliable Signal Transmission Flexible conductive materials are essential for biosensors and rehabilitation devices, maintaining conductivity while conforming to the skin. Moriroku’s conductive rubber offers softness with minimal additive content, making it suitable for extended wear.

-

Soft electrodes for wearable sensors

-

Pads for biosignal detection

-

Antistatic Measures for Medical Devices and Equipment

Factories & Industrial Equipment: For Static Elimination and Grounding Applications*

In manufacturing environments, static elimination and grounding (earthing) measures are essential to prevent damage caused by electrostatic discharge. Flexible conductive rubber is effective as packing or gaskets between equipment, accommodating complex shapes and fine gaps.

-

*

Grounding refers to the process of connecting electrical circuits or equipment to the earth (ground) to stabilize voltage levels and protect against noise or overvoltage.

-

Sheathing materials for connectors and cables

-

Conductive gloves

-

Gaskets

Semiconductor & Cleanroom Industry: Low-Particle Conductive Materials for ESD Control

In semiconductor and precision equipment manufacturing, maintaining an ultra-clean environment is critical—especially to prevent contamination from carbon particle shedding. Conductive rubber using highly dispersed carbon nanotubes (CNTs) offers conductivity while minimizing carbon fallout, making it ideal for applications such as ESD control mats, tool grips, and flexible sealing materials.

-

Pads and packings for electrostatic discharge (ESD) protection

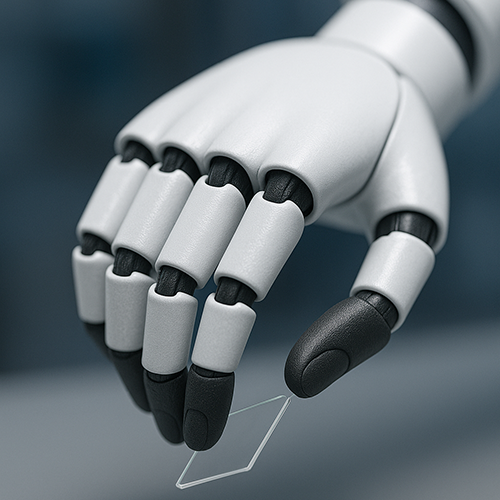

Robotics & Soft Actuators: Safe, Flexible Conductive Components

Robots that frequently interact with humans, as well as soft actuators made from pliable materials, require conductive components that are both flexible and safe. This conductive rubber combines gentle touch with precise signal transmission, making it ideal for next-generation collaborative robots.

-

Robotic arms

Why Moriroku’s High-Dispersion Carbon Masterbatch Is the Material of Choice

-

High conductivity with minimal additive content → Maintains softness

-

Excellent dispersion and uniformity → Effective electromagnetic shielding

Moriroku’s high-dispersion carbon masterbatch is a next-generation material that simultaneously delivers softness, conductivity, and lightweight performance—qualities that are often difficult to achieve together.

It is expected to play a key role in future-focused fields such as next-generation mobility, IoT, healthcare, and smart textiles.

-

Highly dispersed carbon nanotubes

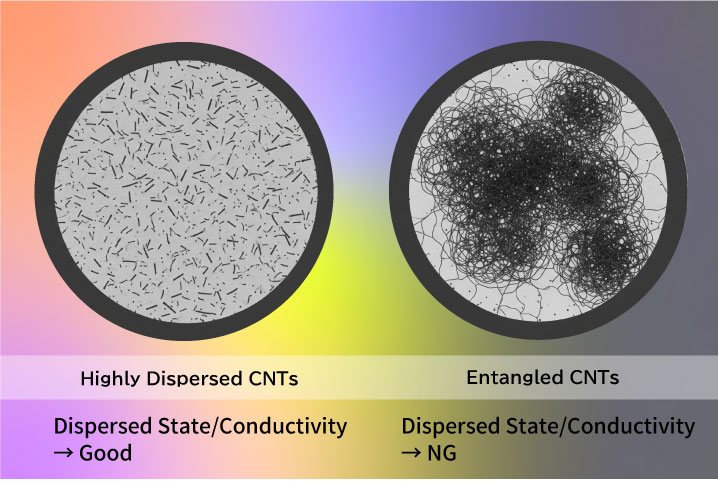

We provide technical information on Moriroku’s high-dispersion carbon nanotube (CNT) masterbatch, including key physical properties and comparative microscope images of pellet surfaces—with and without dispersion treatment—at varying CNT concentrations.

-

A Breakthrough Material for the Future! The Potential of Carbon Nanotubes and Moriroku’s Innovative Technology

Using Moriroku’s proprietary processing method, tangled, ball-like multi-walled CNTs are disentangled and transformed into a non-agglomerated state. These dispersed CNTs are then uniformly distributed within resin and offered as pelletized high-dispersion CNT masterbatch.

Other solutions

-

Expertise as a trading company

[Offering effective solutions by understanding customers]

Moriroku Chemicals combines its expertise in trading, marketing, and logistics with its manufacturing capabilities to create new businesses on the world stage.

-

Expanding business globally

[New technologies and trading opportunities drive Moriroku's global expansion]

As part of its efforts to expand its business globally, Moriroku Chemicals has been operating in Israel for many years as the only trading company specializing in chemicals and plastics.