A Breakthrough Material for the Future! The Potential of Carbon Nanotubes and Moriroku’s Innovative Technology

What Are Carbon Nanotubes (CNTs)—the Dream Material with Extraordinary Properties?

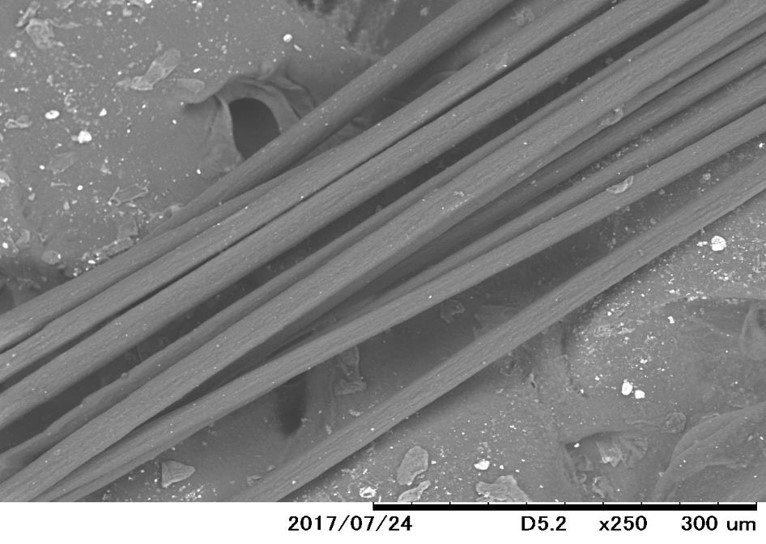

Carbon nanotubes (CNTs) are ultra-thin cylindrical structures made entirely of carbon atoms, with diameters measuring just a few nanometers. This tiny architecture gives rise to astonishing properties.

For example, CNTs are 50 times stronger than steel, have five times the thermal conductivity of copper, and only half the density of aluminum. On top of that, their electrical conductivity can be up to 100 times greater than copper.

In recent years, CNTs have gained attention as conductive additives that enhance the performance of lithium-ion batteries (LiBs), leading to rapid growth in CNT slurry production.

-

*

CNT slurry refers to a liquid dispersion of carbon nanotubes, primarily used in the manufacturing of lithium-ion batteries and conductive materials.

Challenges in Harnessing the Full Potential of CNTs

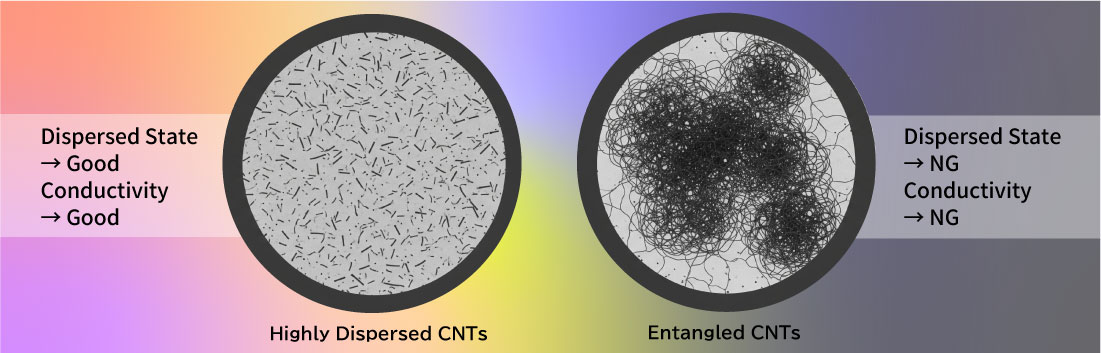

Despite their remarkable properties, carbon nanotubes (CNTs) come with challenges. In particular, relatively low-cost multi-walled CNTs (MWCNTs) tend to form tangled, “ball-like” clusters due to their fine fibrous structure, making uniform dispersion extremely difficult.

When mixed directly into resin, CNTs often become unevenly distributed, preventing their exceptional performance from being fully realized. This has been a key reason why CNTs have not seen widespread use in compound materials such as plastics.

Moriroku’s Breakthrough: “High-Dispersion Carbon Nanotube (CNT) Masterbatch”

Moriroku has developed a groundbreaking technology that addresses a long-standing challenge in CNT utilization.

In collaboration with domestic partner companies, we have devised a proprietary method to untangle the clustered, ball-like multi-walled CNTs (MWCNTs), eliminating agglomeration. These disentangled CNTs are then uniformly dispersed into resin and offered as pelletized “High-Dispersion CNT Masterbatch.”

This innovation unlocks the full potential of MWCNTs, enabling performance comparable to single-walled CNTs (SWCNTs) while maintaining cost-efficiency. It also preserves the physical properties of the base resin.

Benefits of Moriroku’s Highly Dispersed Carbon Nanotube (CNT) Masterbatch

Moriroku’s CNT masterbatch offers significant advantages across a wide range of applications.

1. High performance with minimal dosage |

Exceptional dispersion enables high conductivity even at low additive concentrations. |

|---|---|

2. Contributes to cost reduction |

Compared to conventional products, the required dosage can be significantly reduced, leading to lower material costs. |

3. Supports high-quality manufacturing |

Minimal agglomeration reduces the risk of foreign particles, helping maintain a clean finish and attractive appearance. |

4.Broad customization options |

Tailored to meet customer needs, with adjustable CNT type, concentration, and compatibility with various base resins including PP, PE, PA, PC, and more. Compatible base resins: Polypropylene (PP), Polyethylene (PE), Polyamide (PA), Polyethylene Terephthalate (PET), Polycarbonate (PC), Polyvinyl Chloride (PVC), Acrylonitrile Butadiene Styrene (ABS), Silicone Rubber, Ethylene Propylene Diene Rubber (EPDM), Nitrile Butadiene Rubber (NBR) |

Expanding Applications of Highly Dispersed Carbon Nanotube (CNT) Masterbatch

This advanced technology is expected to find applications across a wide range of industries, including automotive components.

Automotive Components |

Ideal for parts requiring high conductivity, such as power cables and fuel tubes. |

|---|---|

Electromagnetic Shielding (Millimeter-Wave Band) |

With excellent shielding properties, CNTs can be used in housings and enclosures as a lightweight alternative to metals like steel and aluminum. |

Electrostatic Protection |

Outstanding conductivity makes it suitable for anti-static films and other electrostatic discharge (ESD) countermeasures. |

Why Moriroku’s High-Dispersion Carbon Masterbatch Is the Material of Choice

-

High conductivity with minimal additive content → Maintains softness

-

Excellent dispersion and uniformity → Effective electromagnetic shielding

Moriroku’s high-dispersion carbon masterbatch is a next-generation material that simultaneously delivers softness, conductivity, and lightweight performance—qualities that are often difficult to achieve together.

It is expected to play a key role in future-focused fields such as next-generation mobility, IoT, healthcare, and smart textiles.

-

Highly dispersed carbon nanotubes

We provide technical information on Moriroku’s high-dispersion carbon nanotube (CNT) masterbatch, including key physical properties and comparative microscope images of pellet surfaces—with and without dispersion treatment—at varying CNT concentrations.

-

Connecting Electricity with Flexibility: A New Option in Conductive Rubber

Moriroku has successfully unlocked the full potential of carbon nanotubes (CNTs)—renowned for their exceptional conductivity—through its proprietary high-dispersion technology. This innovation enables superior conductivity with significantly lower additive content, while preserving the inherent softness of rubber materials.

他の記事を読む

-

Expertise as a trading company

[Offering effective solutions by understanding customers]

Moriroku Chemicals combines its expertise in trading, marketing, and logistics with its manufacturing capabilities to create new businesses on the world stage.

-

Expanding business globally

[New technologies and trading opportunities drive Moriroku's global expansion]

As part of its efforts to expand its business globally, Moriroku Chemicals has been operating in Israel for many years as the only trading company specializing in chemicals and plastics.